Industrial Automation

We have the capacity to provide turnkey automation solutions within the manufacturing sector comprising of food and beverages, Mining and Cement, Steel and Plastic Processing, Oil Refinery, and Utilities. Our expertise include design, project management, and product support services with the following specialties:

OUR AUTOMATION BRANDS

- PLC programming to process control requirement

- HMI configuration

- SCADA systems design

- Software and firmware upgrade.

- Upgrade of old PLC and SCADA systems, reprogramming and configuration to control system.

- Sizing and selection of control valves and variable speed drives, motion control drives, configuration of local and remote parameters, and integration into automated SCADA system.

PLC PROGRAMMING

Production lines, machine functions, or building management systems is enhanced using PLC based systems. We program PLCs to perform the process required set of tasks under real-time constraints with superior reliability and performance.

We have expertise in various PLC languages such as Function block diagrams, Ladder diagrams, Instruction list, and Sequential function charts.

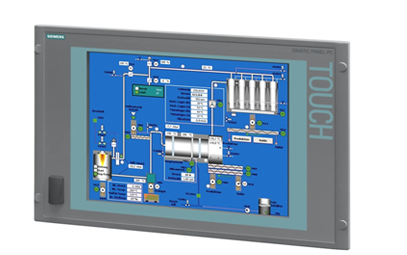

HMI CONFIGURATION

We provide robust and reliable HMI solution that scales from a stand-alone, machine-level HMI to a distributed visualization solution. Our services include technical support for HMI challenges in process, batch and discrete applications to improve on productivity. Our HMI control panels offer effective standard HMI functionality such as

- Alarm and event management

- Graphics

- Animation

- Macro and ladder diagram functionality

- Recipe management

Designed with Microsoft Windows standard of interaction, Compact HMI supports Windows 8.1 and Windows Server 2012 R2. This provides exceptional ease of use, unmatched performance and cost savings .

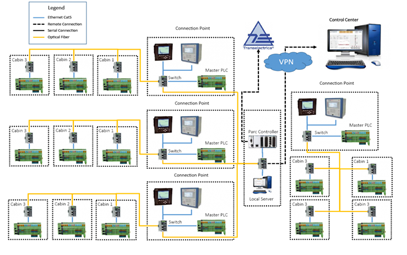

SCADA DESIGN

Production processes in mining, metals, cement, food and beverage, etc. industries have become more complex vis-à-vis the ever increasing quality requirements coupled with fast product changes and frequent modifications.

To ensure the highest possible productivity at the same time, it has to be possible to make prompt, target-oriented decisions regarding process optimization at all levels of production. This requires real-time flow of information across all operating levels using PLCs/SCADA control systems. The SCADA helps to achieve the following functions.

- Control and monitoring of plant processes

- Efficient analysis of process values (Trends)

- Efficient process diagnostics

- Efficient Field Alarm Control

- Energy data management

- Data Archiving